Enhanced Oil & Gas Recovery and Reservoir Characterization

Test/Measurements Systems & Setups

Core Flooding System

The Core Flooding System is configured for the measurement of permeability and capillary pressure, and for liquid/liquid gas/liquid displacements under the conditions of overburden pressures up to 1,000 psi and temperatures up to 150°C (300°F) with Viton sleeves.

Core Flooding System

Automated data acquisition and logging of pressures is controlled by the Labview software. Constant temperature is provided by a convection oven. A high pressure ISCO pump delivers the displacement fluid at various flow rates.

HP-HT CO2 Injection Test System

The High Pressure High Temperature Test System is used for CO2/miscible gas injection under up to 4,000 psi and 232°C (450°F). It consists of high pressure vessels connected to pumps and cylinders and can be used for static or dynamic high pressure solvent injection tests. A DAQ system makes it possible to read temperature and pressure values.

Steam Injection Test System

This system is designed for high temperature steam experiments. The setup consists of a steam generation unit and a high pressure vessel that contains the main sample under test. A DAQ system is also attached to monitor pressure and temperature.

Cyclic Steam Injection System

This system is used for:

-

Cyclic steam injection

-

High temperature (200°C)

-

High pressure (250 psi)

-

Chemical additives (Nano-particle, surfactant solutions, etc.)

Learn more about the research being done with the Cyclic Steam Injection System

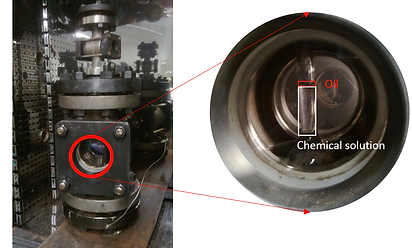

Chemical Addition with Steam Injection System

This system consists of a steam generation unit, a core holder with oil-saturated core, a pressure and temperature controlling unit, a production unit, two syringe pumps for injection, and a data acquisition unit. Chemical solution is co-injected with steam to the core at high temperature (200°C) and high pressure (250 psi).

Oxidation/Diffusion Test System

This system consists of a stainless steel reactor in which an oil-saturated core is introduced and soaked in a gas atmosphere (solvents and air). The system is kept at static conditions and pressure and temperature are measured with time. The reactor is connected to a data acquisition system for data recording. Gas pressure data is analyzed as well as fluid composition to assess the effect of gas mixture in oil recovery by means of a diffusion and gravity drainage mechanisms.

Working pressure and temperature of reactor are 2000 psi and 300°C (572°C).

Visualization of Proppants Transportation in Fractures

This system is used for:

-

Cyclic steam injection

-

High temperature (200°C)

-

High pressure (250 psi)

-

Chemical additives (Nano-particle, surfactant solutions, etc.)

Learn more about the research being done with the Cyclic Steam Injection System

Pore-scale Investigations of Steam Injection

The 10×15 cm and 5×5 cm 2D visual sandpack models were prepared and placed into a transparent vacuum chamber to prevent heat loss. The processes were recorded with a high-speed camera to obtain visual data at the pore scale. This process represents the lateral spreading of the steam chamber during steam-assisted gravity drainage (SAGD) for heavy-oil recovery.

This system is used by Francisco (Paco) Javier Argüelles Vivas. Related publications:

-

Arguelles, F. and Babadagli, T.: “Pore Scale Investigations on the Dynamics of Gravity Driven Steam Displacement Process for Heavy Oil Recovery and Development of Residual Oil Saturation: A 2-D Visual Analysis,” SPEJ 21 (6): 1943-1959.

-

Arguelles, F. and Babadagli, T.: “Experimental and Analytical Modeling of Gravity Drainage Dominated Heavy-Oil Recovery Under Non-Isothermal Conditions: A Micro Scale Approach,” SPE 148872, 2011 CSUG/SPE Canadian Unconventional Resources Conf., Calgary, Alberta, Canada, November 15-17.

-

Arguelles, F. and Babadagli, T.: “Pore Scale Modeling of Gravity Drainage Dominated Flow under Isothermal and Non-Isothermal Conditions,” SPE 153591, 2012 SPE Latin American and Carib. Petr. Eng. Conf. (LACPEC), Mexico City, Mexico, April 16-18,

Working pressure and temperature of reactor are 2000 psi and 300°C (572°F).

HP-HT Pendant Drop Interfacial Tension (IFT) System

The Pendent Drop Interfacial Tension System is used for measuring interfacial tension at reservoir pressure and temperature, up to 10,000 psi and 177°C (350°F). The cell has interchangeable needle tips to achieve a wide measurement range. The lower limit is 10-3 dynes/cm.

HP-HT Pendant Drop Interfacial Tension (IFT) System

The system sits on a vibration-free table. It includes the heating system, metering pumps, and a microscope system with video camera for image viewing, recording, and analysis.

HP-HT Imbibition System

This system is used to visualize imbibition process at high temperature (200°C) and high pressure (500 psi). An oil-saturated core sample and chemical solution are placed inside a glass imbibition cell and the cell is pressurized above the saturation pressure under certain temperature. Different chemicals, such as nano-particle solutions, ionic liquids, etc. can be used.

Learn more about the research used with HP-HT imbibition system

Electromagnetic Heating System

This system is used to enhance the heavy oil recovery by using radio-frequency electromagnetic wave.

Technical Specifications:

Wave frequency: 2.45 GHz

Variable powers: 210-200 W

Fiber optic probes (Neopix T1) for temperature measurement up to 250°C, suitable for applications in electromagnetic field.

Typical applications:

Gravity drainage study of heavy oil under radio frequency electromagnetic heating;

Enhanced heavy oil recovery with nanoparticles under radio frequency electromagnetic heating;

Combination of solvent injection and electromagnetic heating for enhanced heavy oil recovery.

Learn more about the research used with Electromagnetic heating system

3-D Visualization of Diffusion and Dispersion

This system is used to visualize miscible displacement in porous media. Both solvent diffusion under purely static conditions and solvent injection to simulate VAPEX can be studied. This system consists of a laser source, a model contains oil-saturated glass beads, two high speed cameras, and a computer to control the camera's movement.

Learn more about the research used with 3-D Visualization of Diffusion and Dispersion

Micro-Model Visualization Setup

This setup is used to study the interactions of different phases during enhanced oil recovery techniques such as solvent injection or alternative solvent and water injection. In such EOR techniques, several phases exist including matrix grain, solvent, oil and water. Therefore the visualization process requires use of UV light with application of appropriate (water-base or oil-base) tracers. With this method, it is possible to visualize more than three phases in the model.

The micro-model visualization system is composed of a high speed camera mounted on a microscope, a UV light source, syringe pump and the micro-model. The maximum magnification of this system is 2600X. Therefore, with this setup it is possible to visually observe any microscopic change in the residual oil.

HP-HT Mini Bench Top Reactor

This system is used to study the chemical reactions during thermal EOR processes. It is composed of a reaction chamber and the temperature controller. The reaction chamber (600 cc volume) has three valves at the cap that enable taking gas/liquid samples and injection during the process.

The maximum operation condition for this system is 350°C (662°F) and 2000 psi. The System is equipped with a water circulation line that is used to control the temperature. A programmed heating/cooling of the reactor is possible with the temperature controller.

HP-HT Pendant Drop Interfacial Tension (IFT) System

PVT Cell is precision manufactured laboratory equipment designed specifically for the measurement of fluid properties and the study of fluid phase behavior. The instrument provides a means of accurately measured and sample fluid phases at controlled temperature and pressures. Measurements of interest include various vapour/liquid physical properties such as density, vapor/liquid ratios, and independent phase compositions.

HP-HT Pendant Drop Interfacial Tension (IFT) System

In addition, the PVT Cell has a glass tube that is connected with CCD level measurement system Long Focus and AverMedia DVD EXMaker 7 to capture the fluid visualization. Other applications such as deasphalting process have been carried out using the PVT cell. Moreover, the machine has connection to a high pressure and high temperature filter to do the asphaltenic components separation.

SARA Analysis Setup

The saturates, asphaltenes, resins and aromatics (SARA) from the medium oil, heavy oil and bitumen samples can be analyzed by our research group following the ASTM 2007 D and ASTM D2549.

To carry out the SARA test, the following instruments are used: muffle furnace, soxhlet extractor, chromatography columns, desiccator, rotary-evaporator, filtration system, and vacuum pump.